Concrete Steel Fiber

Key words:

Concrete Steel Fiber

Classification:

Description

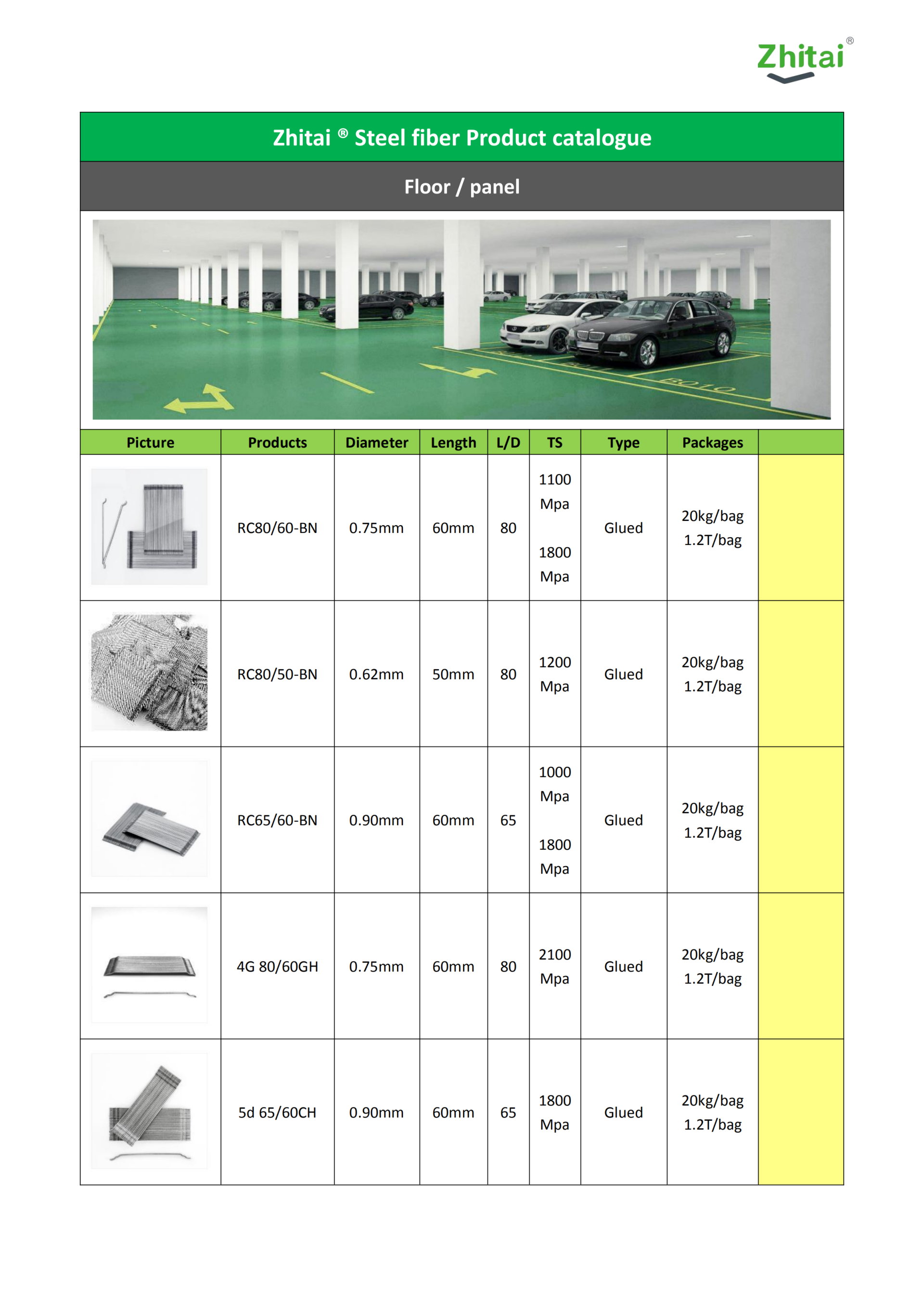

steel fibres for precast concrete

The spray layer supported by steel fiber shotcrete is more in line with the concept of "flexible support". The steel fiber endows the supporting layer with a certain ductility

Application

• Tunnel safety support

The spray layer supported by steel fiber shotcrete is more in line with the concept of "flexible support". The steel fiber endows the supporting layer with a certain ductility, which can not only absorb the energy brought by the deformation of the surrounding rock, but also mobilize and stimulate the self-stabilizing ability of the surrounding rock by fitting the surrounding rock.

• Simple and quick construction

The steel fiber shotcrete replaces the hanging net construction, which not only saves the cost of hanging nets, but also reduces the risk of rockfall injury. At the same time, the steel fiber shotcrete can be constructed quickly in the first time, can be closed in time, and quickly stabilize the surrounding rock.

• Smaller rebound and less consumption

The rebound of steel fiber shotcrete is smaller than that of hanging net shotcrete, and the molding of concrete is more compact. And there is no need to backfill the over-excavated part, which greatly saves the consumption of concrete.

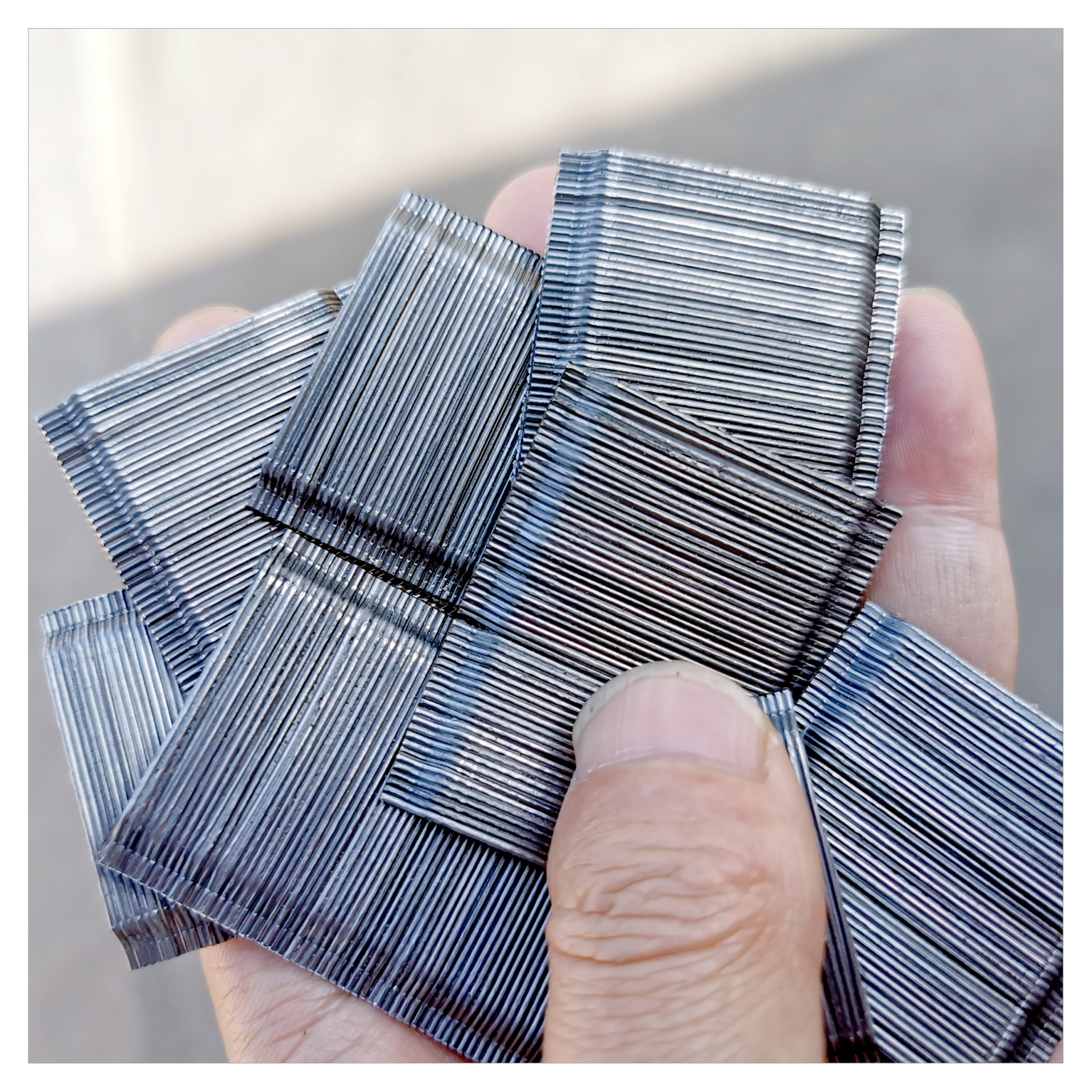

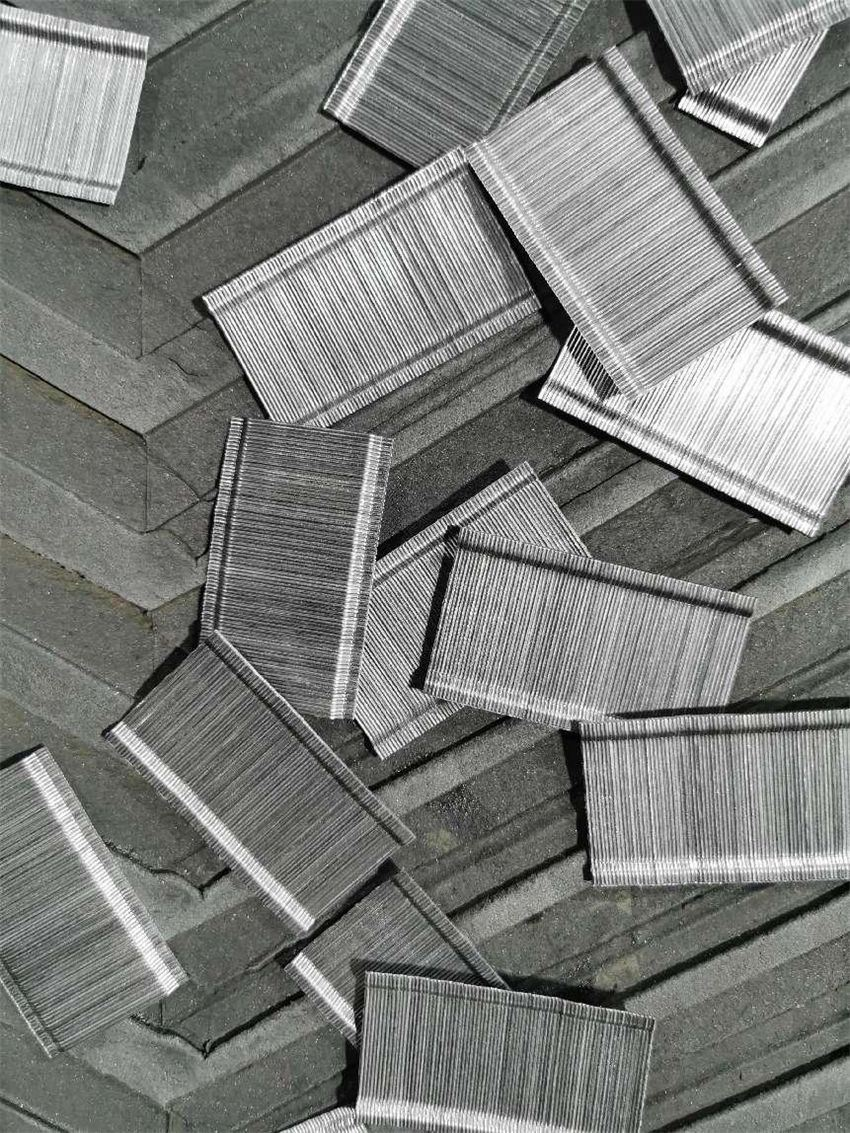

Steel fiber is a widely used reinforcement material in modern concrete construction, designed to improve the mechanical properties and durability of concrete structures. Composed of small, discrete steel filaments, steel fibers are added directly to the concrete mix to enhance its tensile strength, toughness, and resistance to cracking under stress. Unlike traditional steel reinforcement, which requires placement of rebar, steel fiber is evenly distributed throughout the concrete, providing multidirectional reinforcement and reducing weak points that may lead to cracks or structural failures.

The primary benefit of steel fiber reinforced concrete is its ability to control shrinkage and cracking. Concrete naturally tends to shrink and develop microcracks as it cures and dries. Steel fibers act as internal reinforcement, bridging microcracks and distributing stress more evenly across the structure, which minimizes the formation of larger cracks and improves long-term durability. This feature is particularly valuable in industrial floors, pavements, tunnels, and precast concrete products, where durability and impact resistance are critical.

Steel fiber also enhances the concrete’s toughness and impact resistance. In applications subject to dynamic loads, heavy traffic, or machinery vibration, steel fiber reinforced concrete can withstand repeated impact and fatigue better than conventional concrete. This makes it suitable for warehouse floors, airport runways, highway pavements, and industrial slabs. Additionally, steel fibers improve the post-cracking behavior of concrete, allowing it to carry loads even after initial cracking, enhancing structural safety and reliability.

Installation and mixing of steel fiber reinforced concrete are straightforward. Fibers are added during the batching process and mixed thoroughly to ensure uniform distribution. Steel fiber concrete does not require special handling equipment beyond standard concrete mixers, and it integrates seamlessly with existing construction processes. Various types of steel fibers, including hooked, crimped, and straight fibers, are available to suit specific structural and performance requirements.

In summary, steel fiber is a versatile and effective reinforcement material that significantly improves the strength, durability, crack resistance, and impact performance of concrete. By integrating steel fibers into concrete mixes, engineers and builders can create longer-lasting, safer, and more resilient structures across a wide range of construction applications.

Pre

Pre

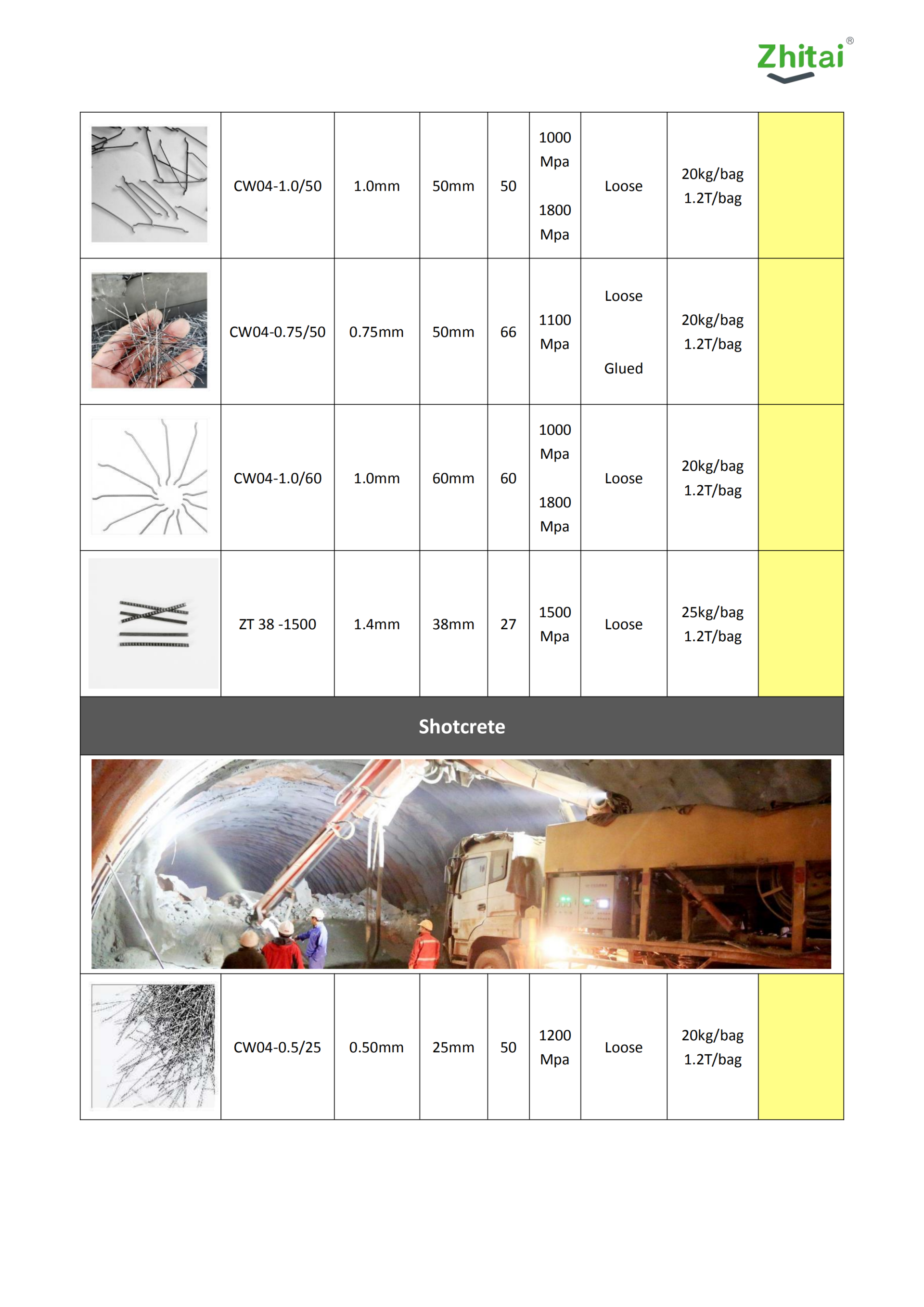

Steel Fiber for shotcrete

Next Page