Cold Drawn Steel Wire Fibre

Key words:

Cold Drawn Steel Wire Fibre

Classification:

Description

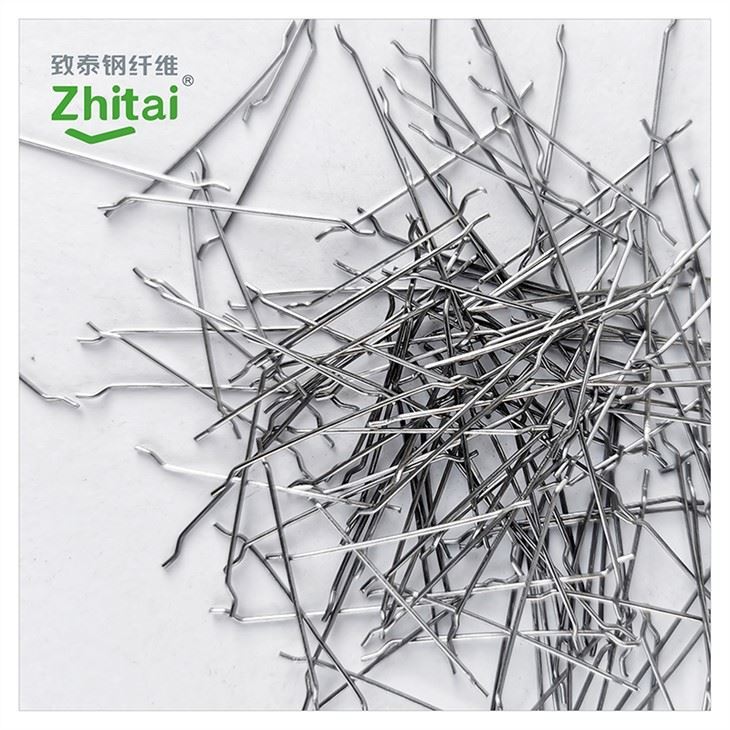

Cold Drawn Steel Wire Fibre

After layer-by-layer tests, the optimal length and diameter matching were selected to ensure the monofilament state and avoid clumping after stirring. Meet routine load requirements at the lowest cost

Application

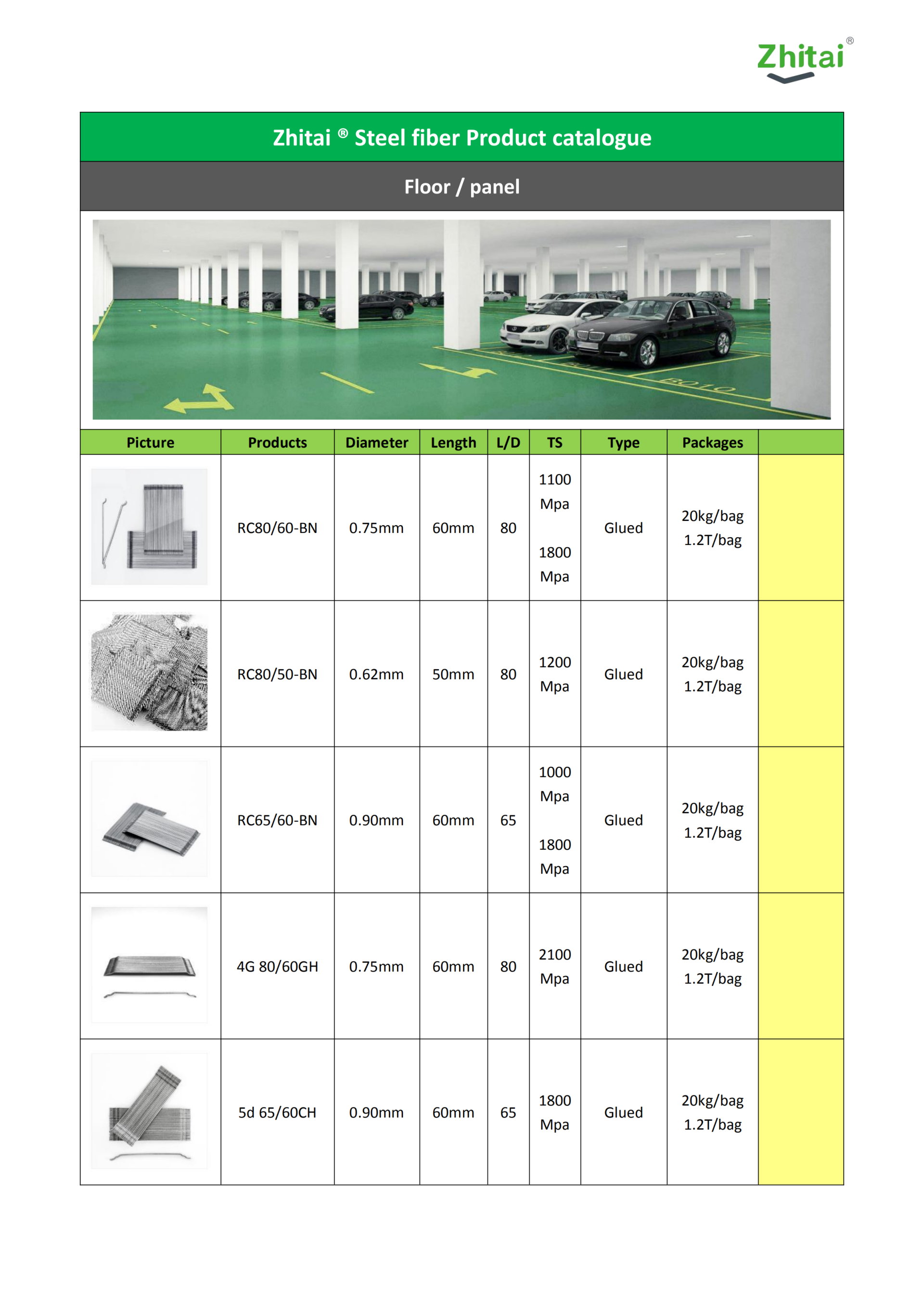

• Perfect balance between performance and cost

After layer-by-layer tests, the optimal length and diameter matching were selected to ensure the monofilament state and avoid clumping after stirring. Meet routine load requirements at the lowest cost.

• The most economical choice for thin top coats

For structures with low loads or thin concrete surfaces, the use of longer fibers is limited. This model is an excellent choice for thin finishes. It is often used as an adhesive finish for building surfaces or floor renovations.

• Ideal for compound reinforcement solutions

Building structures using reinforced steel fiber composite reinforcement solutions are often limited by the cost of construction and the workability of steel fiber reinforced concrete. We select the ideal model for the composite reinforcement solution for you, saving the cost of the gap where the steel fiber reinforced concrete can easily pass through the rebar.

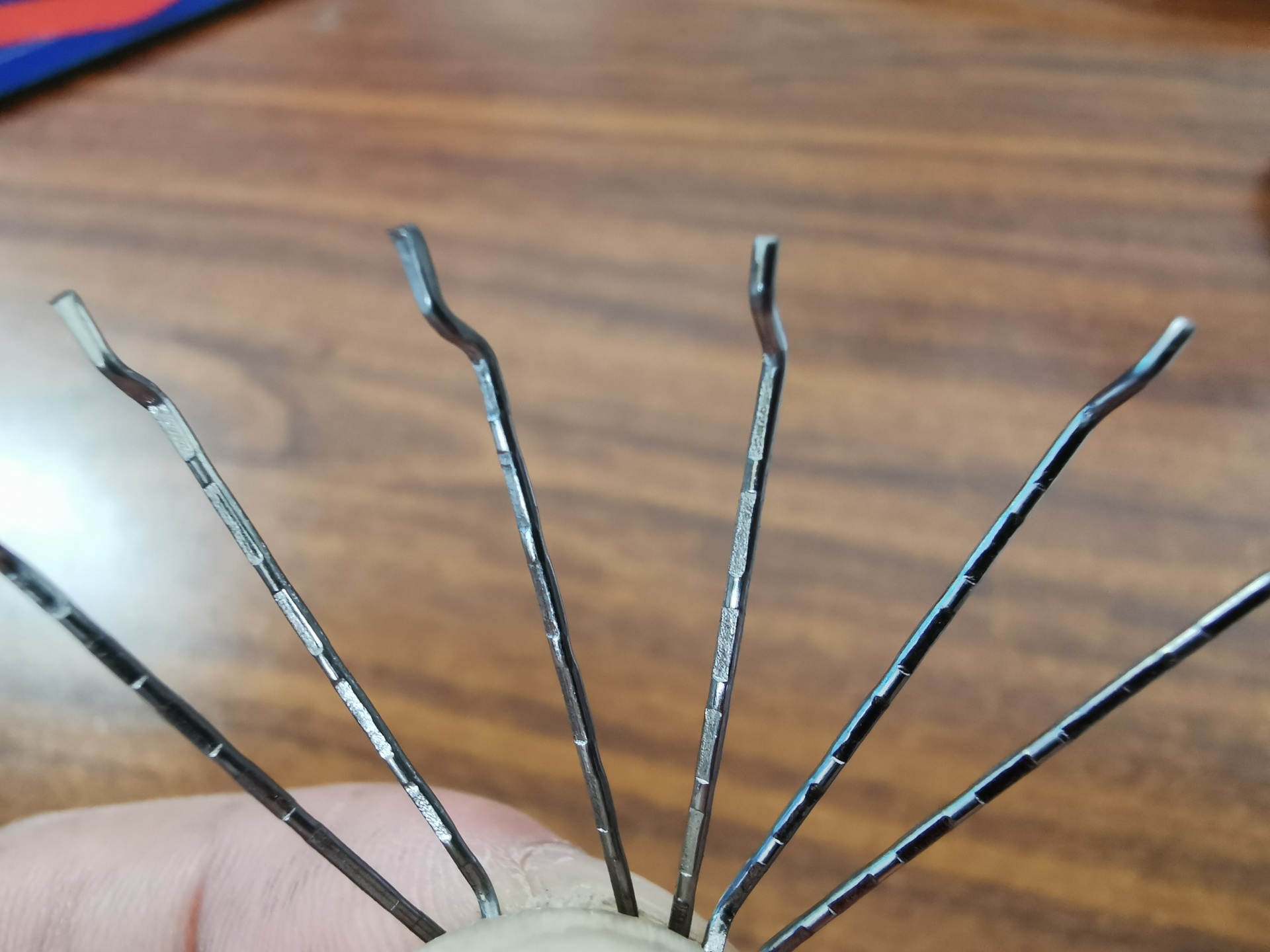

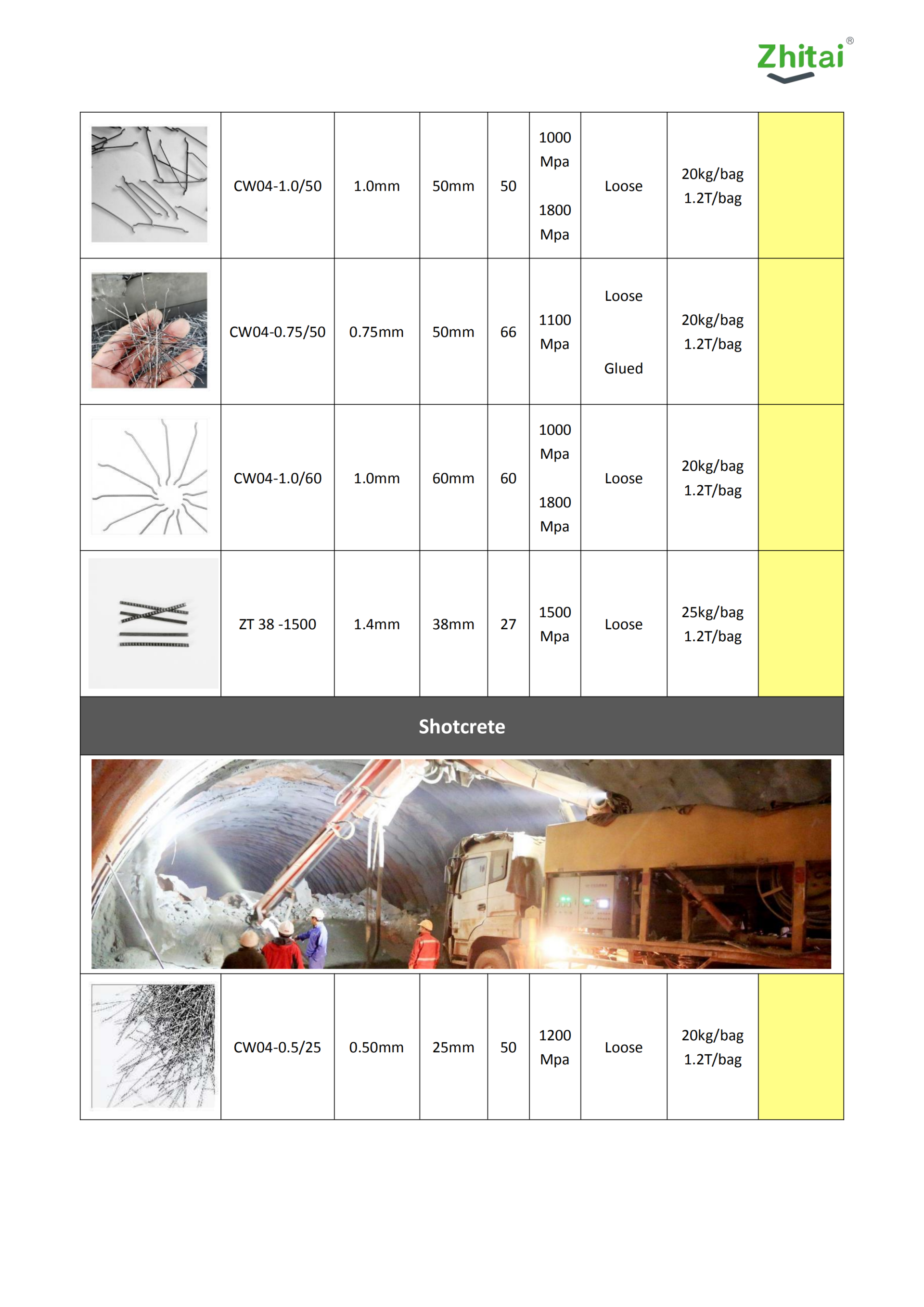

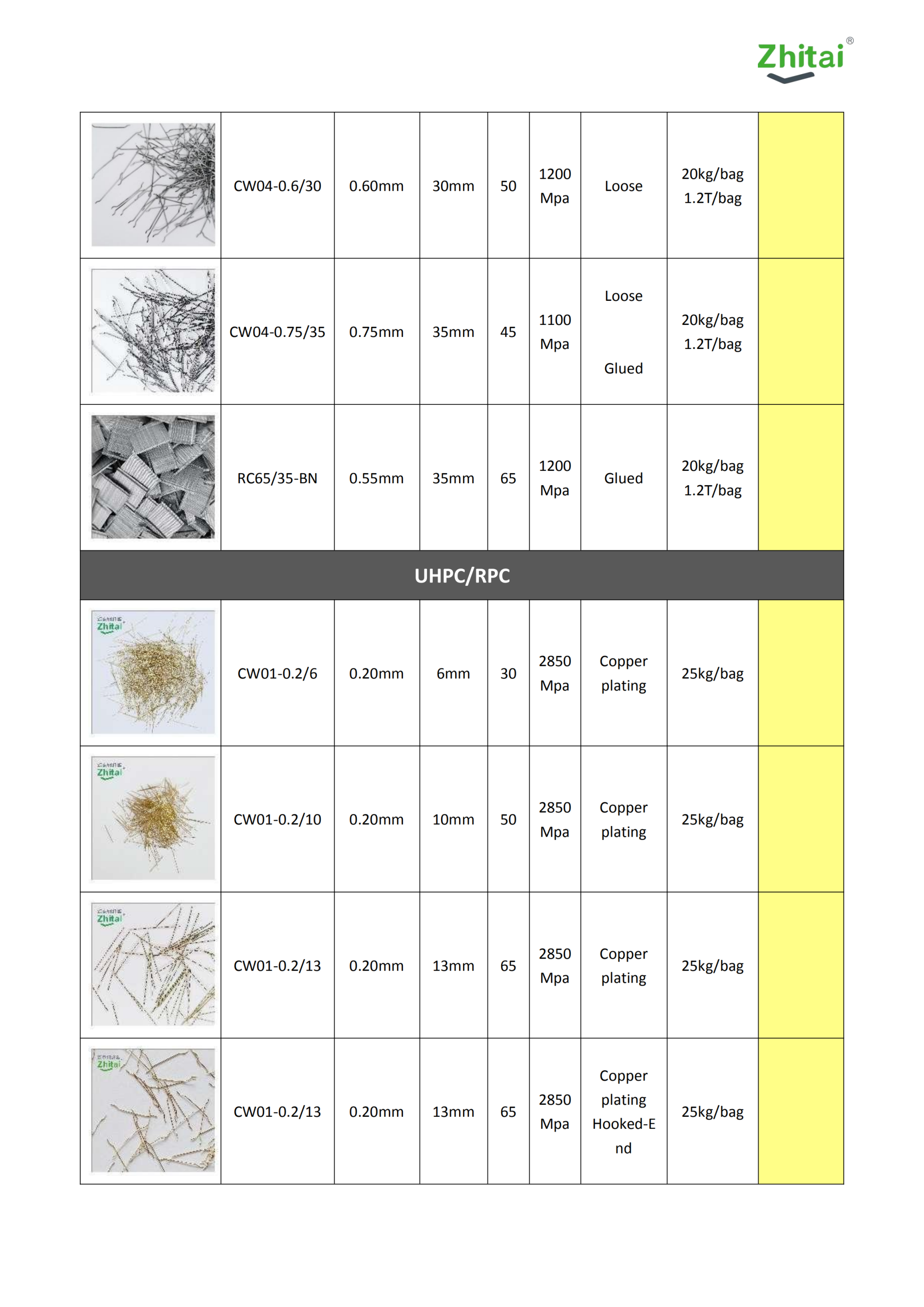

Cold drawn steel wire fibre is a high-performance reinforcement material widely used in modern concrete construction. Manufactured by drawing high-quality steel wire through a series of dies at room temperature, this process increases the tensile strength and flexibility of the steel fibres. When incorporated into concrete, cold drawn steel wire fibres enhance its structural integrity, improve crack resistance, and extend the service life of construction elements.

One of the primary advantages of cold drawn steel wire fibre is its ability to control cracking in concrete. Micro-cracks that naturally develop due to shrinkage, temperature changes, or load stress are minimized, reducing the risk of structural failure. These fibres distribute stress uniformly across the concrete, preventing localized weak points and improving overall toughness. This property is particularly valuable in industrial floors, precast elements, tunnels, and bridge decks, where durability and long-term performance are critical.

In addition to crack control, cold drawn steel wire fibres enhance impact resistance, fatigue strength, and load-bearing capacity of concrete structures. They are effective in both reinforced and unreinforced concrete, reducing reliance on conventional steel bars in certain applications. The fibres’ uniform dispersion ensures consistent performance throughout the concrete matrix, contributing to higher safety and reliability.

Cold drawn steel wire fibres are easy to handle and mix into fresh concrete without affecting workability. They are corrosion-resistant, compatible with various concrete mixes, and suitable for use in both indoor and outdoor projects. By reducing maintenance needs and extending the service life of concrete structures, these fibres offer a cost-effective and sustainable solution for modern construction demands.

In summary, cold drawn steel wire fibre is an essential material for high-performance concrete applications. Its ability to improve crack resistance, structural strength, and durability makes it a preferred choice for engineers and contractors seeking long-lasting and reliable concrete solutions.

Pre

Pre

Concrete 4D steel fiber

Next Page